One of the best and shortest explanations of what Lean is really about, I’ve found in the “This is Lean” book by Niclas Modig and Per Åhlström.

The thing that made it “click” for me was a diagram that contrasted Resource efficiency with Flow efficiency. I love it! Even though I might have talked about Efficiency versus Effectiveness… Well, it’s not my book—maybe that’s why it’s famous and I’m not.

Basically:

- Scoring high on Resource efficiency is, for example, a melting plant for steel. You want that running all the time. You keep a lot of material ready to be processed because the plant is so expensive to shut down.

- Scoring high on Flow efficiency is, for example, the fire department. Most of the time they have enormous overcapacity, just sitting around waiting until they are needed. We want much less work waiting (none) than our capacity.

- Scoring low-low (lower left) means that nothing gets done and there’s also nothing to do. There’s only waste in our process and no value gets created. The desert, if you will.

- Scoring high-high (upper right) means that work gets done just as it’s needed and everyone has just enough to do. There’s no waiting times and no waste in our process. One-piece continuous flow is an example of this Nirvana-like state.

With that diagram in place, we can describe Lean: Lean is a business strategy to reach the Nirvana state by focusing on flow efficiency. Since it’s a strategy, there are other ways to get there, but Lean focuses on Flow efficiency.

If you think that sounded wise and good, it’s because it’s not me; it’s Niclas and Per. Buy the book and thank them.

Now I can finally write my blog post. For years, I’ve been teaching this, trying to focus on Flow Efficiency: keep your stock low, limit work in process, and move things fast through the process. Which made me more surprised when yesterday I found myself saying:

This should never be empty. In fact, I want as many things as possible in here.

At my current “client,” we are trying to implement a focus on quality and continuous improvement in small steps. So far it works, but I wanted to formalize it a bit. On our board, we created a new lane, “Improvements.”

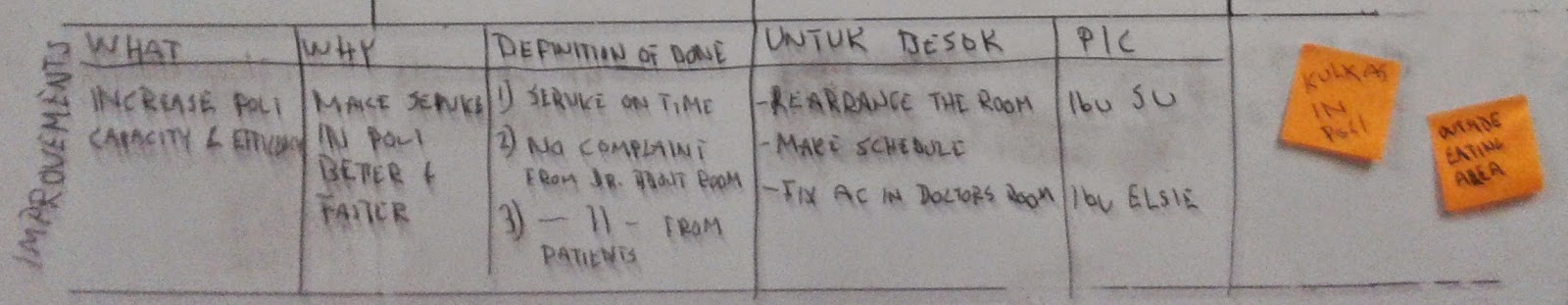

It’s the last lane of our board. We have two other lanes for other things we need to focus on, and it looks like this:

Explanation

- What: We write what we are trying to change. We only do one improvement at a time and try to finish it within 2-3 days. If not, we break it down further.

- Why: The rationale for the change. Why did we think this was a good idea?

- Definition of Done: Helps us know when the change is completed and what kind of measurements we will see.

- Untuk Besok (Until Tomorrow): The list of tasks we will complete until the next meeting (tomorrow morning).

- PIC (Person in Charge): The person we will ask about the status tomorrow morning.

The most important part of this lane is to the far right: Nanti (Next). Here are the things we will try after this improvement.

For a Lean advocate like myself, I cringed a little when I realized:

- I want this lane always working.

- I never want the Nanti column to be empty.

- In fact, I want many things in there.

After some thought, I realized the problems with having too many things in the Nanti column: we don’t know what to choose. But I’d rather have too many improvement ideas than no improvement ideas. We will still limit work in process to just one item at a time to make the changes small and speedy.

We have already found this very useful, helping us focus on the improvement at hand (leaving the other ideas to the side for now), and encouraging smaller steps and changes. But most of all, always having things that we are improving.